Functions

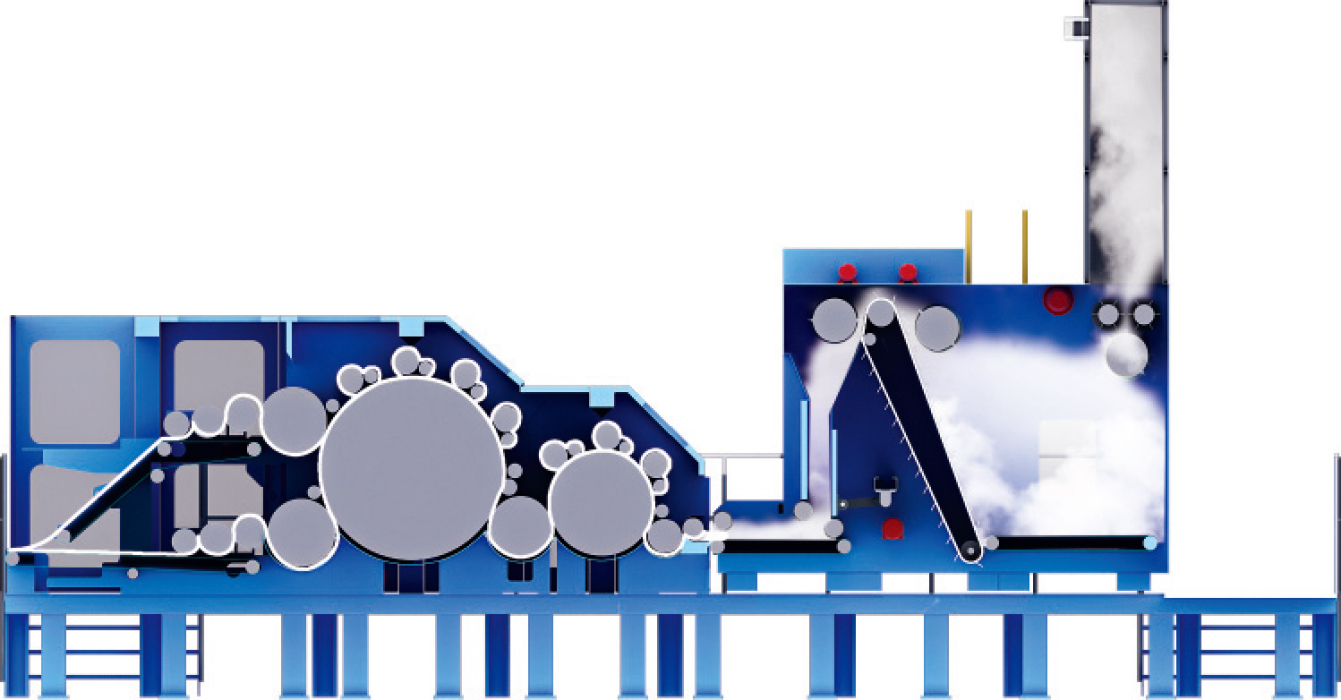

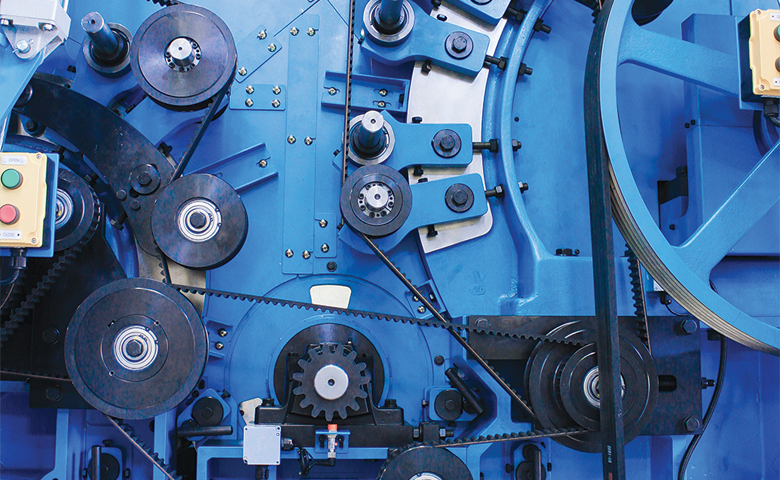

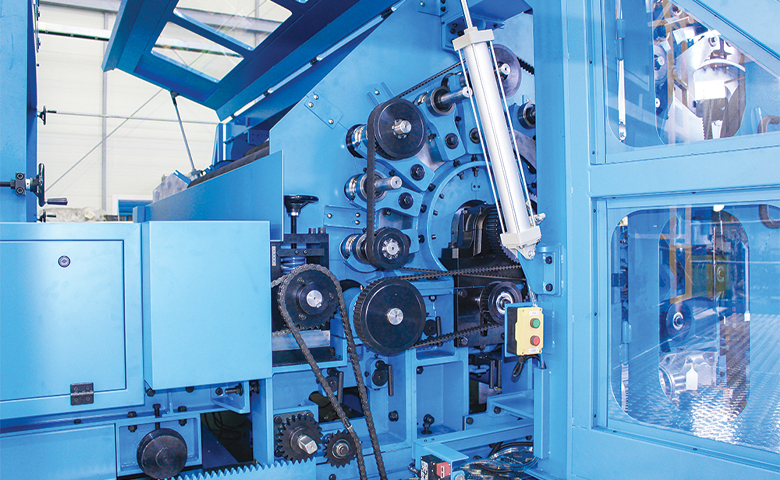

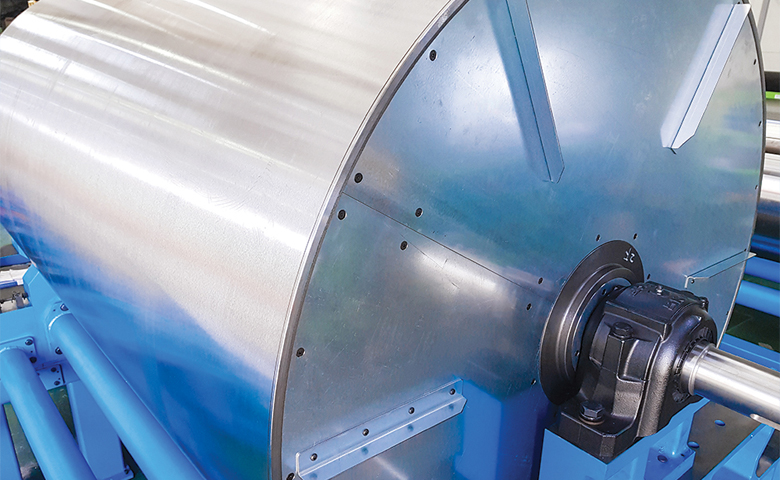

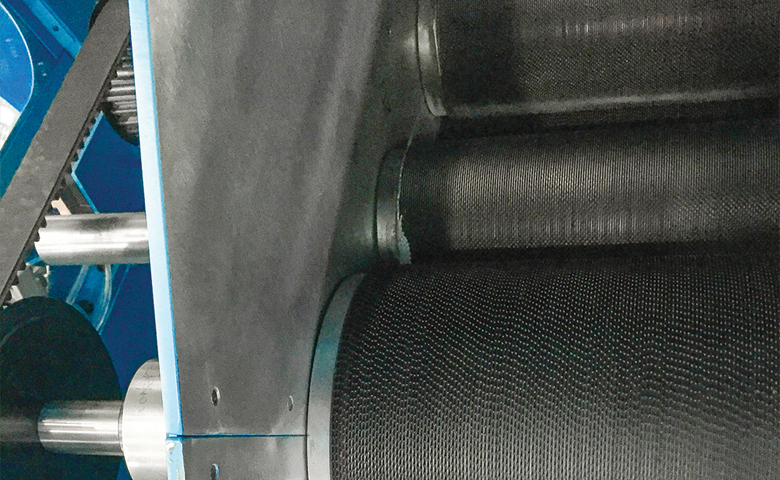

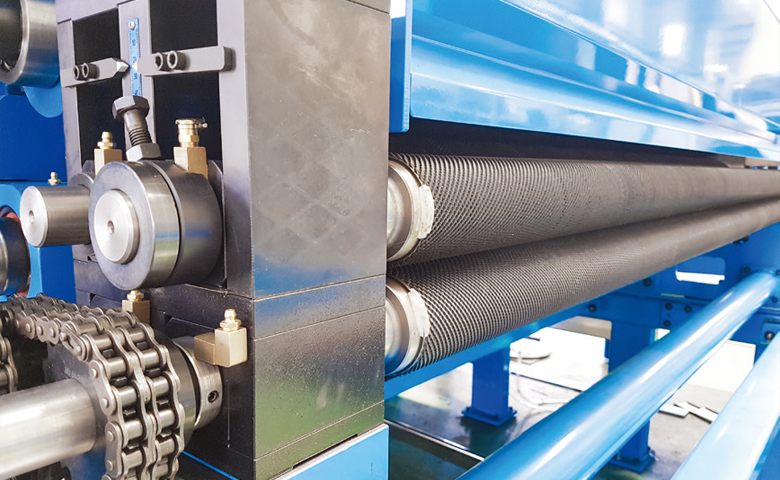

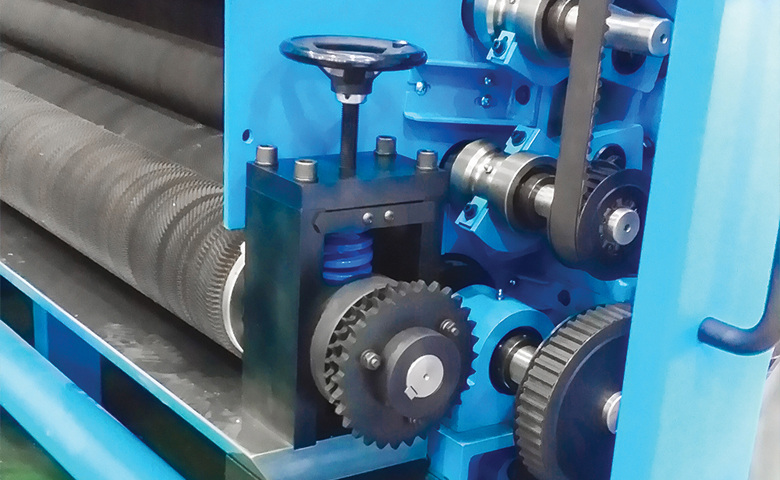

- · Opened fiber is carded by turning the roller with a sharp wire wound.

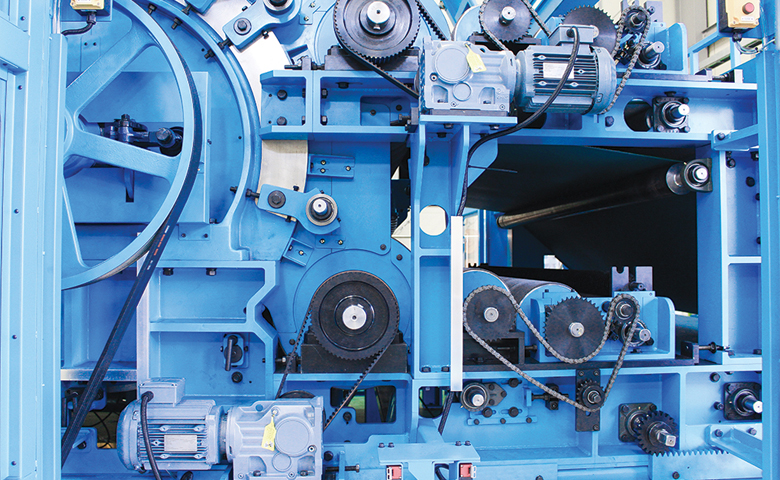

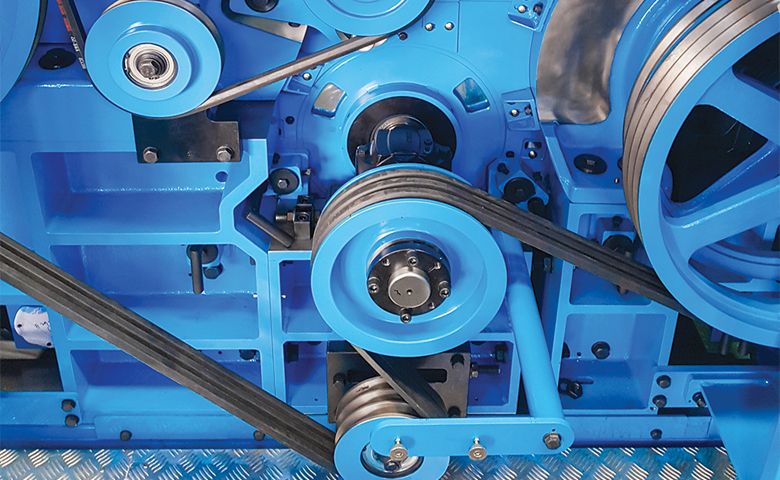

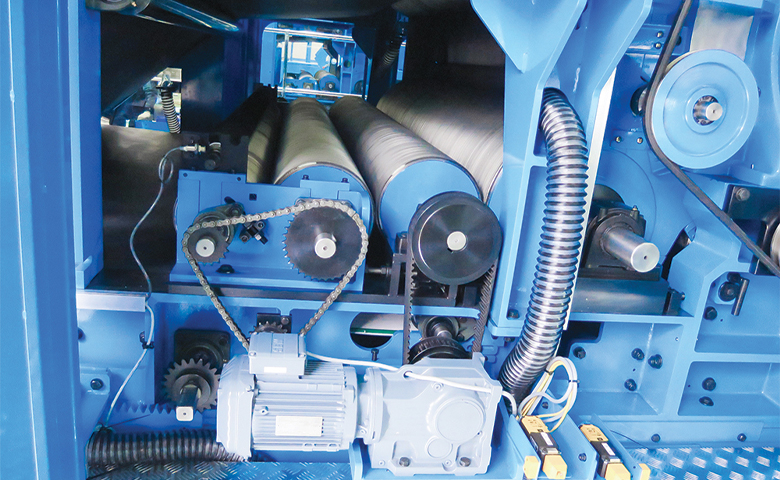

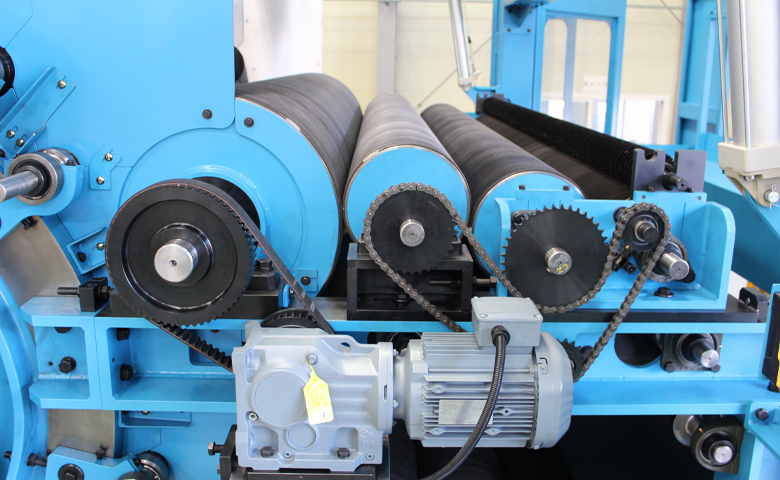

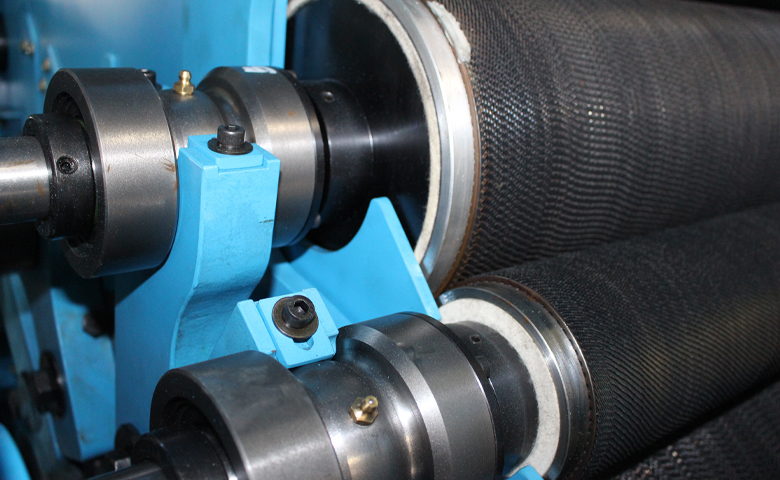

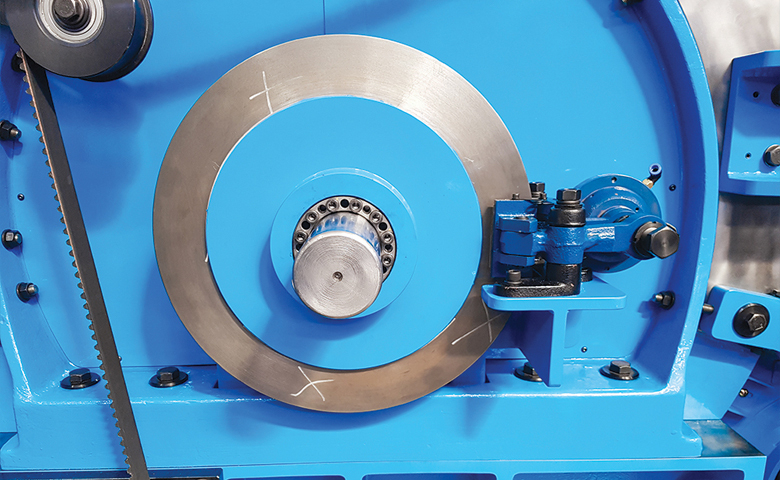

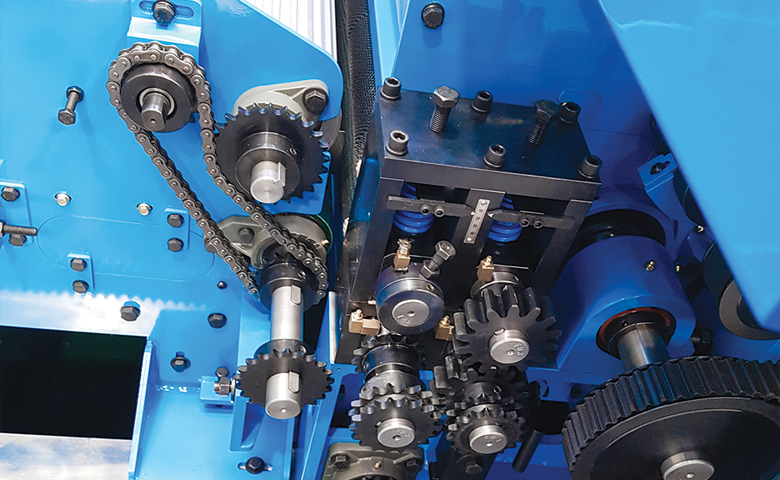

- · Different types of rollers have different direction and speed of rotation, and specifications of wound wire are also different.

- · Fiber is firstly combed by coarse wire & slow speed roller and is combed by the second with fine wire & fast speed roller, thus the bundled fiber is spread straightly.

- · Through a doper and a condenser, an equilibrium or random web is formed and supplied to the next process.

- · It is possible to card all types of fiber from low denier to high denier, including synthetic fiber and natural fiber.

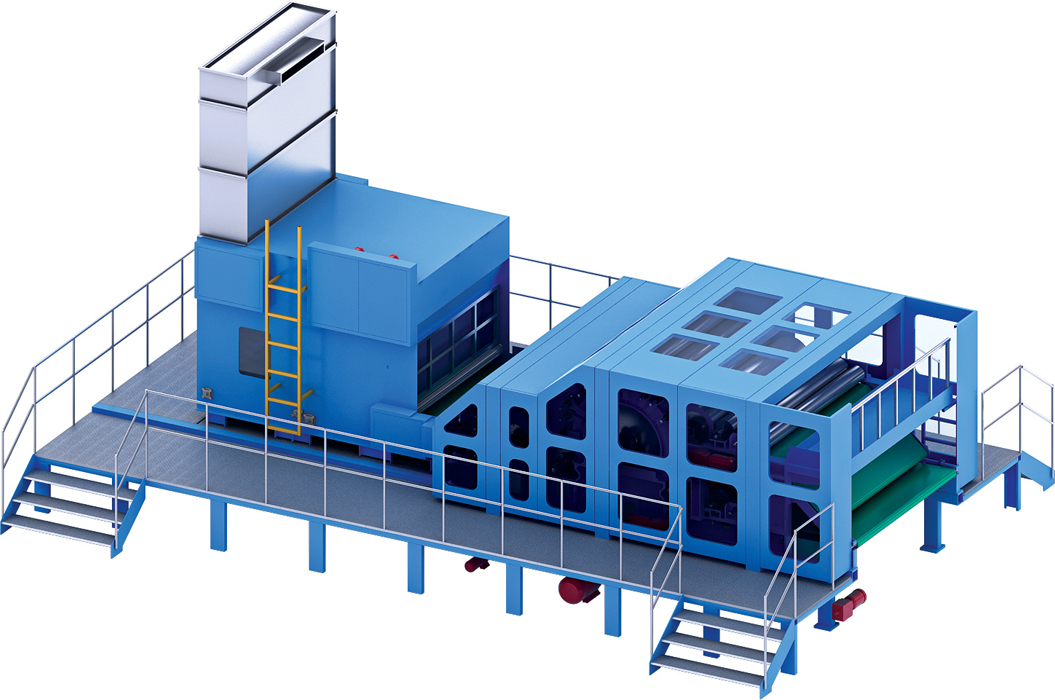

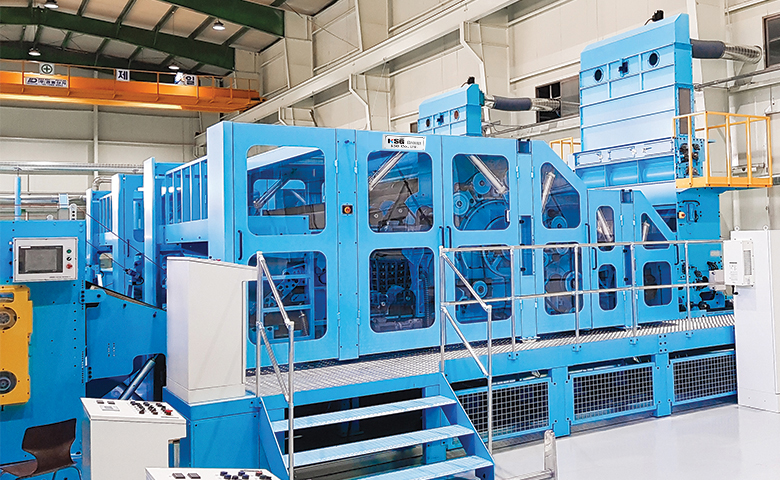

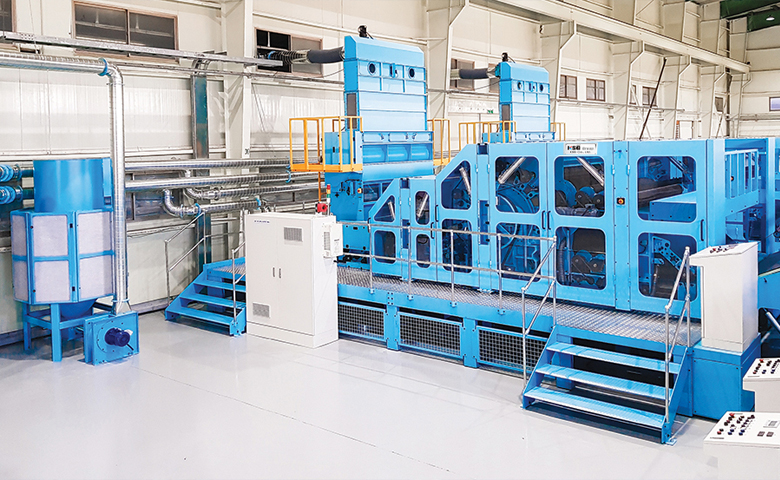

Configuration and Characteristics

- · Wire specifications are different depending on the type of fiber, such as thickness and length.

- · Feed type is 4Roller Type for High Denier and Nose bar type for Low Denier.

- · All feeds are equipped with a metal detection device, which detects metal material and stops feeding the fiber.

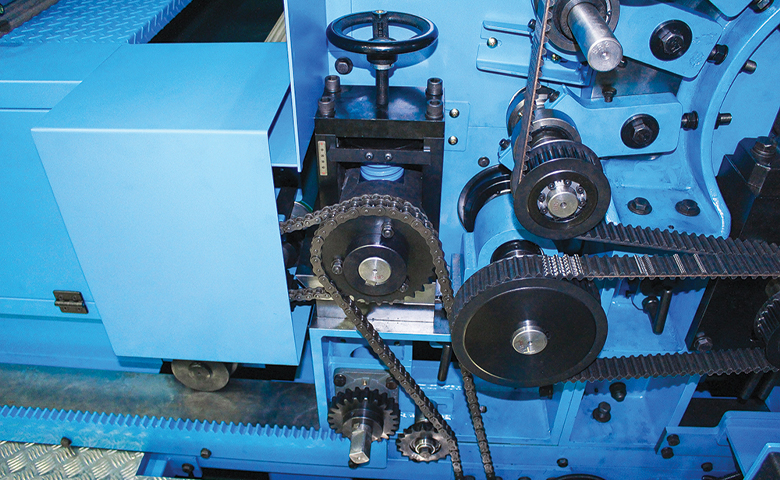

- · The motor offers the best control by applying the best product, EURO Drive.

- · The surface speed of the main cylinder of the card is 1300m/ min, the web weight is 15~50g/m2, and the web production speed is 70m/min.

- · The easy-to-operate control panel is easy to operate. (The Touch Screen function is constantly improved to provide the best possible control.)

- · The control system is an inverter drive and it does not break the fiber as it coincides with the start and end of the entire process by applying the interlocking device.

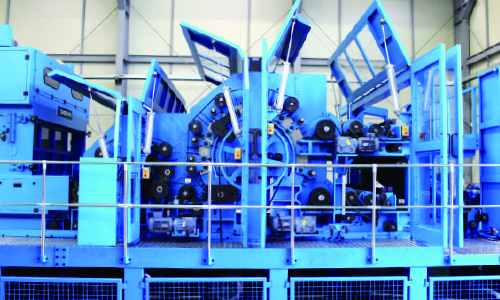

- · Operation of the door lock and sensor eliminates hazards to protect the driver and minimizes emergency stopping time.

- · Wool packing and in-side suction devices on the roller side provide optimal carding conditions and guarantee the shortest time to clean.

- · The suction system removes the fibers and dust from the card continuously, therefore it can be recycled, cleaned easily, and the best carding is possible considering the convenience of operation.